Carbon dioxide capture

Flexible PVC compounds present a unique opportunity to contribute significantly to reduce or even revert carbon dioxide emissions. Due to the low fossil carbon content of PVC resin, as ~56% of the mass is chlorine, the effect of bio-based plasticizers is significant in promoting sequestration of carbon dioxide from the atmosphere.

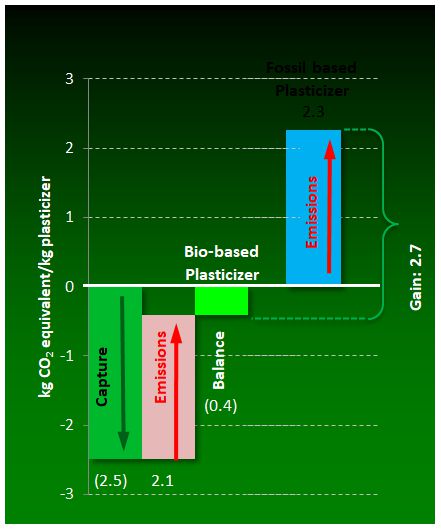

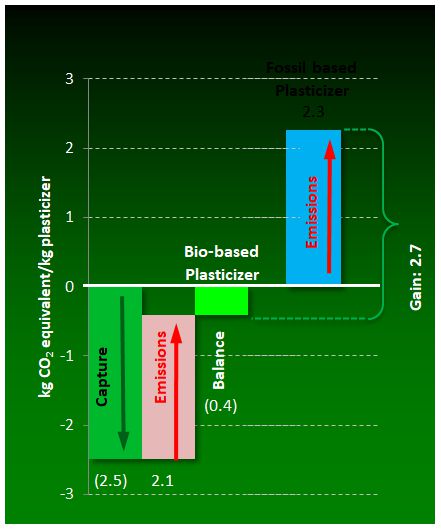

The chart shows the basic calculations to determine the carbon dioxide capture potential of Innoleic

TM products.

The basis for this calculation was the average transportation and production emissions in Brazil, from cradle to gate. In Brazil, transportation is all done by trucks, and the soybeans are distant from the final products production facilities. The total value of emissions includes all phases of the production, from planting and harvesting the soybeans, considering land use, through oil extraction, and to the processing to obtain the final plasticizer. The production of bio-based plasticizers has low energy consumption, as reactions are carried out in less severe conditions of temperature and pressure.

The estimate for the petroleum-based emissions takes into account all operations from the crude extraction to the refined intermediates to the final plasticizer. There is no carbon dioxide absorption in the case of petroleum-based materials.

For each kg of bio-based plasticizers, approximately 0.4 kg of carbon dioxide is removed from the atmosphere until that final article is burned or degraded. For durable goods, such as flooring and upholstery, the cycle could last many decades. On top of that, flexible PVC can easily be recycled, providing an even further environmental benefit, extending significantly the absorption cycle.

The net gain shown in the chart represents the potential carbon dioxide emissions reduction, combining the elimination of the emissions generated by fossil-based plasticizers and the gain obtained by the use of bio-based plasticizers. For each kg of bio-based plasticizers replacing a fossil-based material, we have a reduction of 2.7 kg of carbon dioxide emissions.

If we consider

bio-attributed PVC resins replacing fossil-based resins, the effect is even greater.

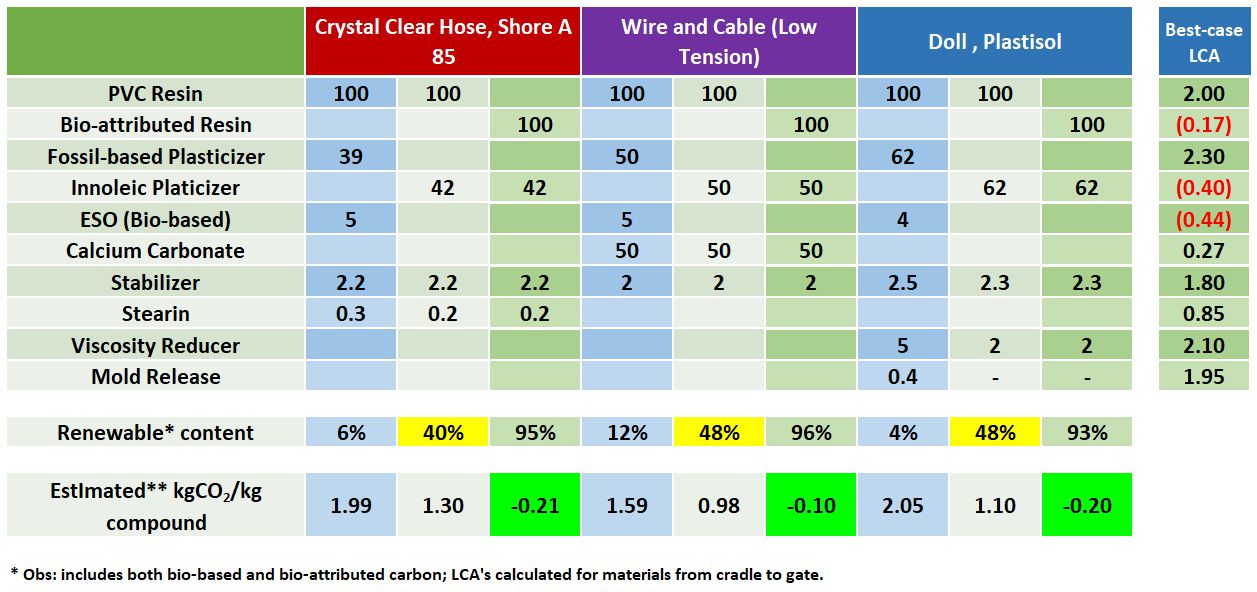

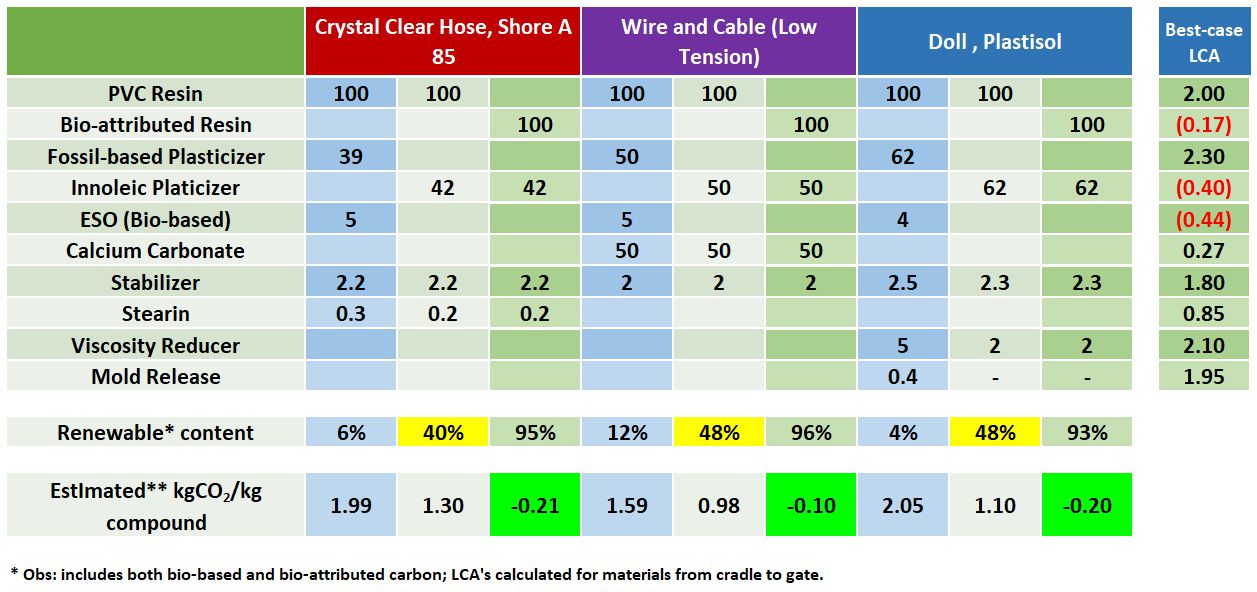

The table below shows some interesting examples of petroleum-based plasticizer substitutions and the overall effect on the carbon footprint as well as bio-based content

Flexible PVC compounds present a unique opportunity to contribute significantly to reduce or even revert carbon dioxide emissions. Due to the low fossil carbon content of PVC resin, as ~56% of the mass is chlorine, the effect of bio-based plasticizers is significant in promoting sequestration of carbon dioxide from the atmosphere.

Flexible PVC compounds present a unique opportunity to contribute significantly to reduce or even revert carbon dioxide emissions. Due to the low fossil carbon content of PVC resin, as ~56% of the mass is chlorine, the effect of bio-based plasticizers is significant in promoting sequestration of carbon dioxide from the atmosphere.