Coated fabrics can be produced with plastisol spread coating or extrusion coating. For plastisols, paste viscosity and ageing are key for the quality of the final product and adequate operations. InnoleicTM products are suitable for plastisol applications, but require special atention to ensure proper formulation adjustments to obtain the ideal rheology.

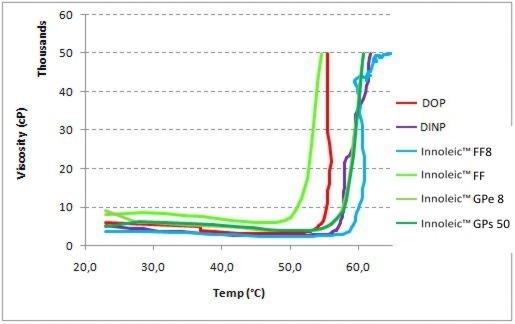

Coated fabrics can be produced with plastisol spread coating or extrusion coating. For plastisols, paste viscosity and ageing are key for the quality of the final product and adequate operations. InnoleicTM products are suitable for plastisol applications, but require special atention to ensure proper formulation adjustments to obtain the ideal rheology. The chart shows the time to gel formation of compounds formulated with different plasticizers. It is clear that InnoleicTM FF presents a much faster gel rate than most traditional plasticizers. But the gel rate of the other materials is fairly similar.

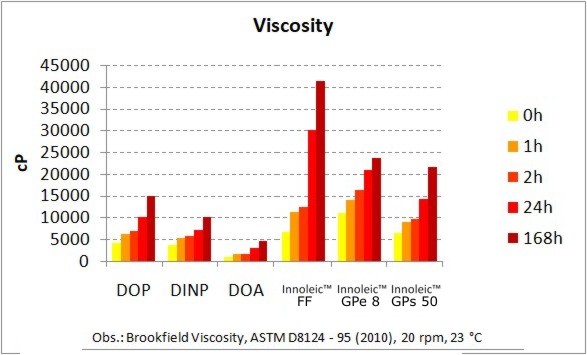

The chart shows the time to gel formation of compounds formulated with different plasticizers. It is clear that InnoleicTM FF presents a much faster gel rate than most traditional plasticizers. But the gel rate of the other materials is fairly similar.  The chart shows the viscosity ageing (up to 168 hours) of compounds formulated with different plasticizers. As expected, the higher efficiency of InnoleicTM products promotes increased viscosity ageing, except for InnoleicTM E8. This can be adjusted, though, with the proper selection of resins, as demonstrated in the chart below.

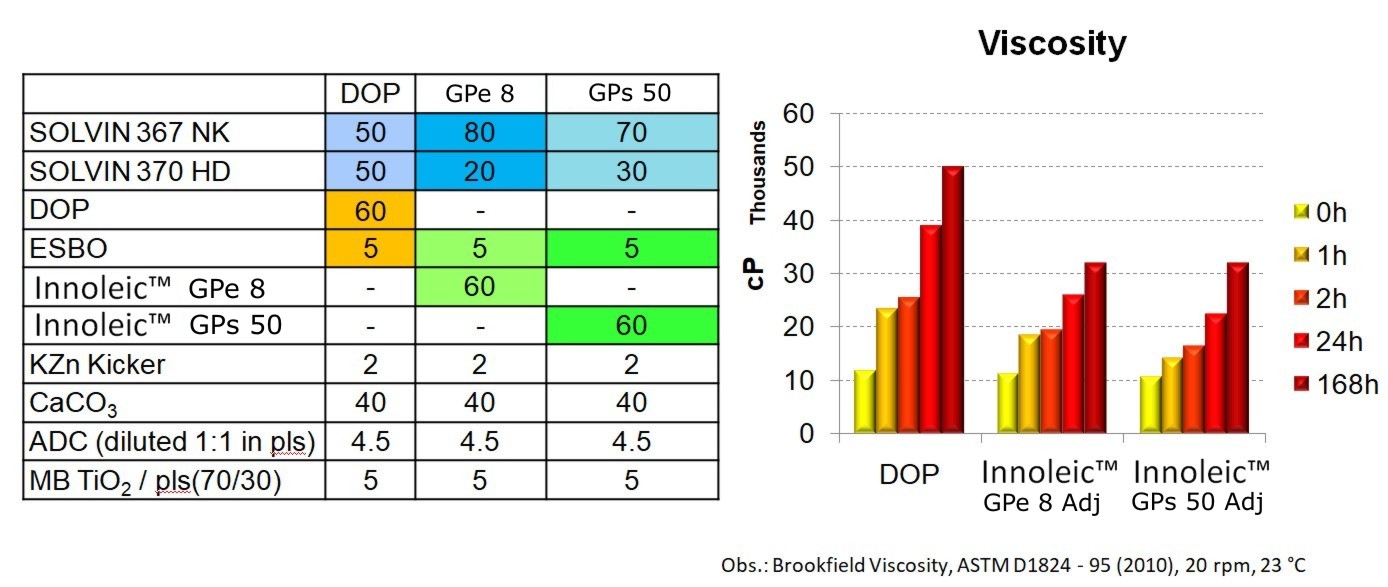

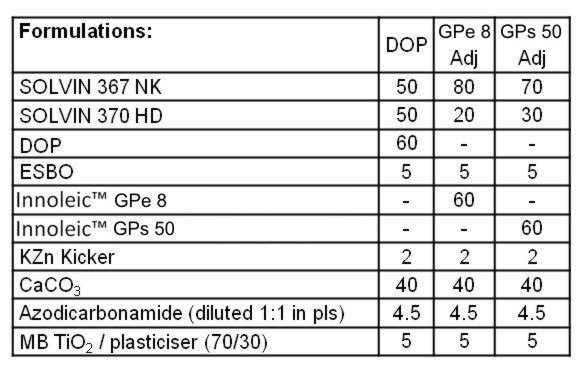

The chart shows the viscosity ageing (up to 168 hours) of compounds formulated with different plasticizers. As expected, the higher efficiency of InnoleicTM products promotes increased viscosity ageing, except for InnoleicTM E8. This can be adjusted, though, with the proper selection of resins, as demonstrated in the chart below.

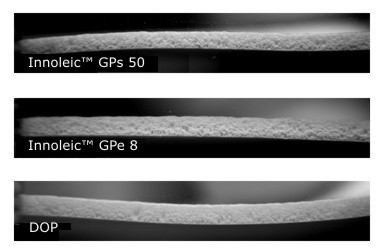

The adjustment required to obtain high quality foamed plastisol layers using InnoleicTM is also on the viscosity. The use of different quantities of kickers or foaming agents did not significantly impact the size and quality of the foam cells. The adjustment of viscosities, on the other hand, was very effective to match or even improve cell quality and size of foam layers.

The adjustment required to obtain high quality foamed plastisol layers using InnoleicTM is also on the viscosity. The use of different quantities of kickers or foaming agents did not significantly impact the size and quality of the foam cells. The adjustment of viscosities, on the other hand, was very effective to match or even improve cell quality and size of foam layers.

Innoleics does not guarantee the typical (or other) values. Any data included herein is based upon analysis of representative samples and not the actual product shipped. The information in this document relates only to the named product or materials when not in combination with any other product or materials. We based the information on data believed to be reliable on the date compiled, but we do not represent, warrant, or otherwise guarantee, expressly or impliedly, the merchantability, fitness for a particular purpose, freedom from patent infringement, suitability, accuracy, reliability, or completeness of this information or the products, materials or processes described. The user is solely responsible for all determinations regarding any use of material or product and any process in its territories of interest. We expressly disclaim liability for any loss, damage or injury directly or indirectly suffered or incurred as a result of or related to anyone using or relying on any of the information in this document.